Use coupon code MOISTURIZER with your purchase of $40 or more for a free†

Blemish Clear MoisturizerQuality & Safety

Quality Natural Products

As a leading natural products company, our dedication to superior quality at value prices has propelled us from a local health food store to an industry leader offering the absolute best variety of high-quality supplements, essential oils, foods, and more.

THE NOW PROMISE: QUALITY, SUSTAINABILITY, AND TRANSPARENCY

What Quality Natural Products Means at NOW

Natural at NOW means products that are as close to nature as possible without harmful levels of toxic substances.

High-Quality Starts with Clean Ingredients

Our strict requirements for ingredient quality and comprehensive scientific processes ensure that every lot of ingredients accepted into our facilities meets our stringent specifications.

Comprehensive Levels of Testing

Our state-of-the-art, in-house laboratories test everything from raw ingredients to finished products to ensure that what’s on the label is in the bottle or package.

Superior Manufacturing

NOW meets and exceeds the FDA's CGMPs to underscore our commitment to quality. NOW was one of the first companies to be CGMP certified by a third party.

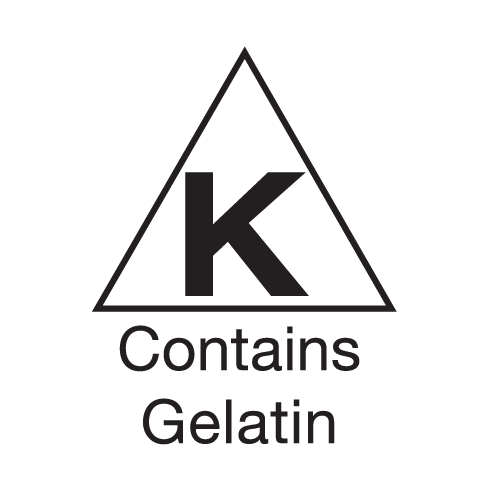

THIRD PARTY CERTIFICATIONS

OUR PROCESS FROM START TO FINISH

Echinacea Part 1: Wild Crafting | NOW Path to Product Quality

Echinacea Part 2: Roots to Raw Materials | NOW Path to Product Quality

Echinacea Part 3: Quality on the Shelf | NOW Path to Product Quality

Amazon Testing - Buyers Beware

NOW tests various supplement brands sold on Amazon and finds many fail for potency and other quality issues.

*These statements have not been evaluated by the Food and Drug Administration. These products are not intended to diagnose, treat, cure or prevent any disease.